Chemical Machinery

Kilia Chemical Machineryprovides a robust and versatile range of equipment for chemical processing, granulation, and pre-cutting. Designed for both industrial-scale and R&D applications, machines like the GRANU 100, GRANU 200 and GRANU 300 offer high-throughput granulation with advanced features such as stainless steel construction, automatic lubrication, PLC control, and Industry 4.0 integration. The PreCutter Rotary complements these systems with high-capacity sheet cutting for SAP and similar materials. With options for automated cleaning, additive spraying, and remote monitoring, Kilia’s chemical machines ensure precision, hygiene, and efficiency across continuous production environments.

GRANU 100 – R&D Granulation Machine

The GRANU 100 is a compact, high-performance granulator designed for research and development or small batch production. It handles up to 1,000 kg/h and is built from SUS 316 stainless steel for chemical and food-grade hygiene. The machine features a polished hopper, angled screws for optimized flow, interchangeable cutting systems, and automatic spray systems for additives or cleaning. It includes PLC control, central lubrication, frequency-controlled drives, and optional hydraulic screw discharger. Remote control via Industry 4.0 integration and a separate stainless steel switch cabinet enhance usability and maintenance.

GRANU 200

The Kilia GRANU 200 is a mid-range granulation machine designed for continuous chemical processing with a capacity of up to 6 tons per hour. It features an integrated ventilation system for effective cooling during operation and supports an automatic cleaning system for improved hygiene and reduced downtime. The GRANU 200 can be seamlessly integrated into Kilia’s PLCM platform, enabling Industry 4.0 connectivity for remote monitoring, process optimization, and smart control.

GRANU 300

The GRANU 300 is a heavy-duty granulation machine built for 24/7 operation with capacities up to 12 tons per hour. It includes a heat-insulated hopper, oil cooling, automatic lubrication, and sensors for process monitoring. The main worm is made from high-resistance stainless steel, and the surface treatment ensures easy cleaning and reduced chemical corrosion. An automatic liquid spraying system simplifies cleaning and maintenance, making it a reliable solution for continuous chemical granulation.

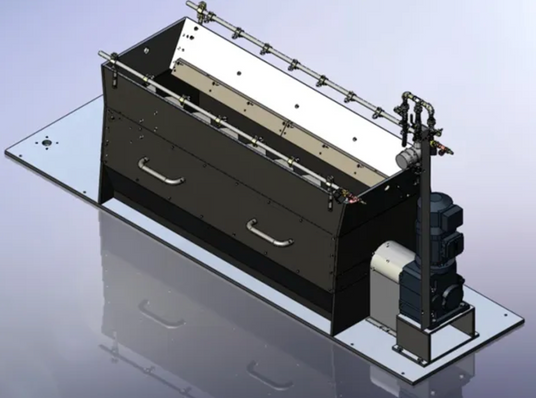

PreCutter Rotary

The Kilia PreCutter Rotary is a high-capacity cutting unit designed for upstream processing in SAP belt reactors. It reduces material into rectangular sheets approximately 300 × 1500 mm, with a throughput of up to 12,000 kg/h. Built from special-grade stainless steel, it features a zig-zag rotary knife system, optional liquid spray for additives, and a robust rotating cutting mechanism. It’s ideal for efficient pre-processing in chemical production lines.