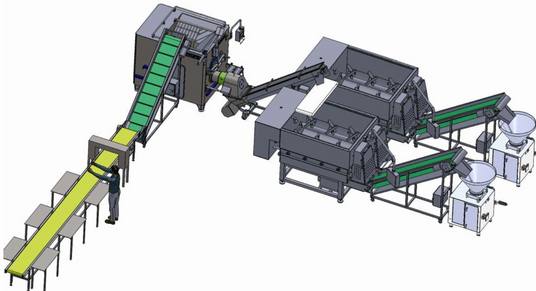

The Kilia Burger Production Line is designed to streamline the manufacturing of high-quality burger products. It begins with the Frozen Meat Grinder W 300, which efficiently processes frozen meat blocks to prepare them for further mixing. A Metal Detector is integrated into the line to ensure product safety by identifying and removing any metal contaminants. The ground meat is then transferred to a 2000-liter Vacuum Mixer, which blends ingredients under vacuum conditions to enhance texture and extend shelf life. Finally, the mixture is portioned and filled using a Vacuum Filler, which maintains product integrity and consistency during packaging.

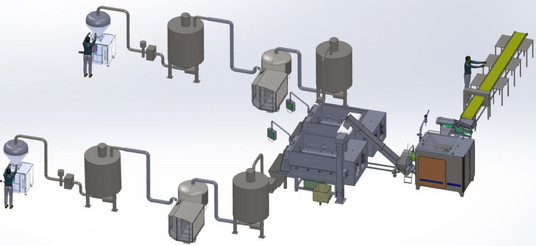

The Kilia Sausage Production Line is tailored for larger-scale sausage production and includes additional components to support more complex processing. Like the burger line, it starts with the Frozen Meat Grinder W 300 and a Metal Detector for safety. However, it features a 3000-liter Vacuum Mixer, offering greater capacity for high-volume operations. The line also includes 3000-liter Silos for intermediate storage and handling of the mixed product, allowing for smoother workflow and batch management. A Vacuum Emulsifier is used to achieve a fine, uniform texture essential for sausage products. The process concludes with a Vacuum Filler, ensuring precise and hygienic portioning.